Introduction

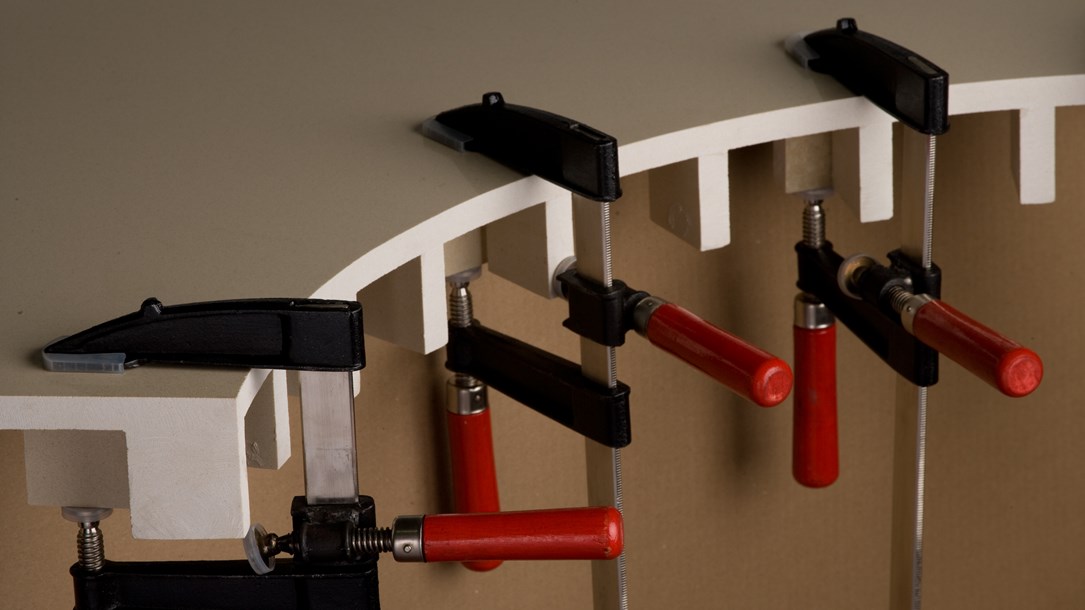

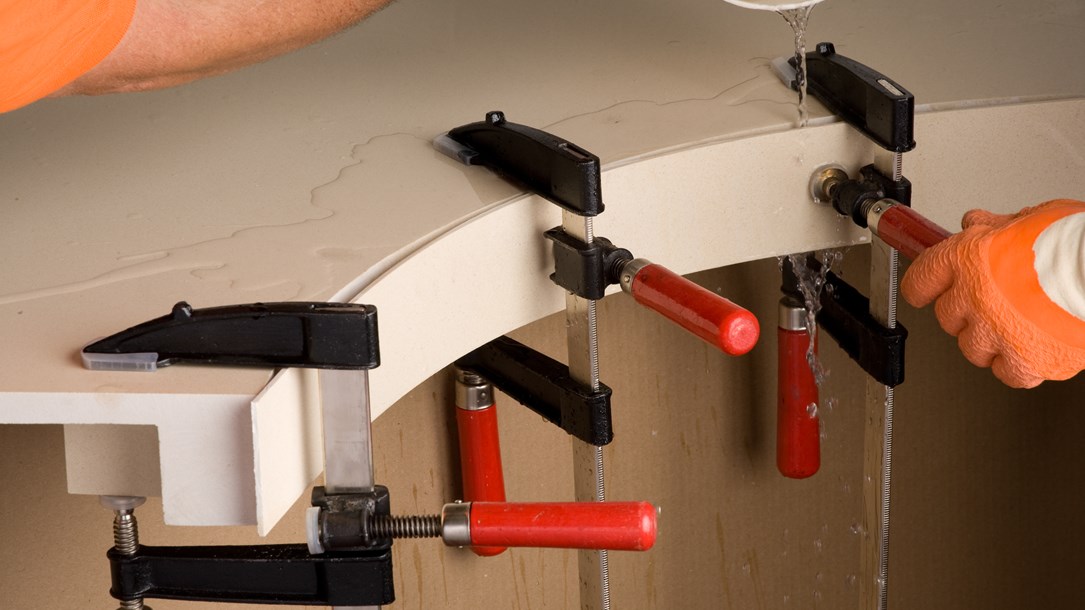

Thermoforming Caesarstone quartz, Caesarstone MineralTM or Caesarstone ICONTM surfaces is the process of heating a straight surface and forming it into a curved surface. The material becomes flexible when the thickness is sufficiently reduced and it is heated to the right temperature. Caesarstone quartz, Caesarstone MineralTM and Caesarstone ICONTM surfaces can be formed to create almost any shape imaginable.